Project Details

Project

Industrial Systems Automation

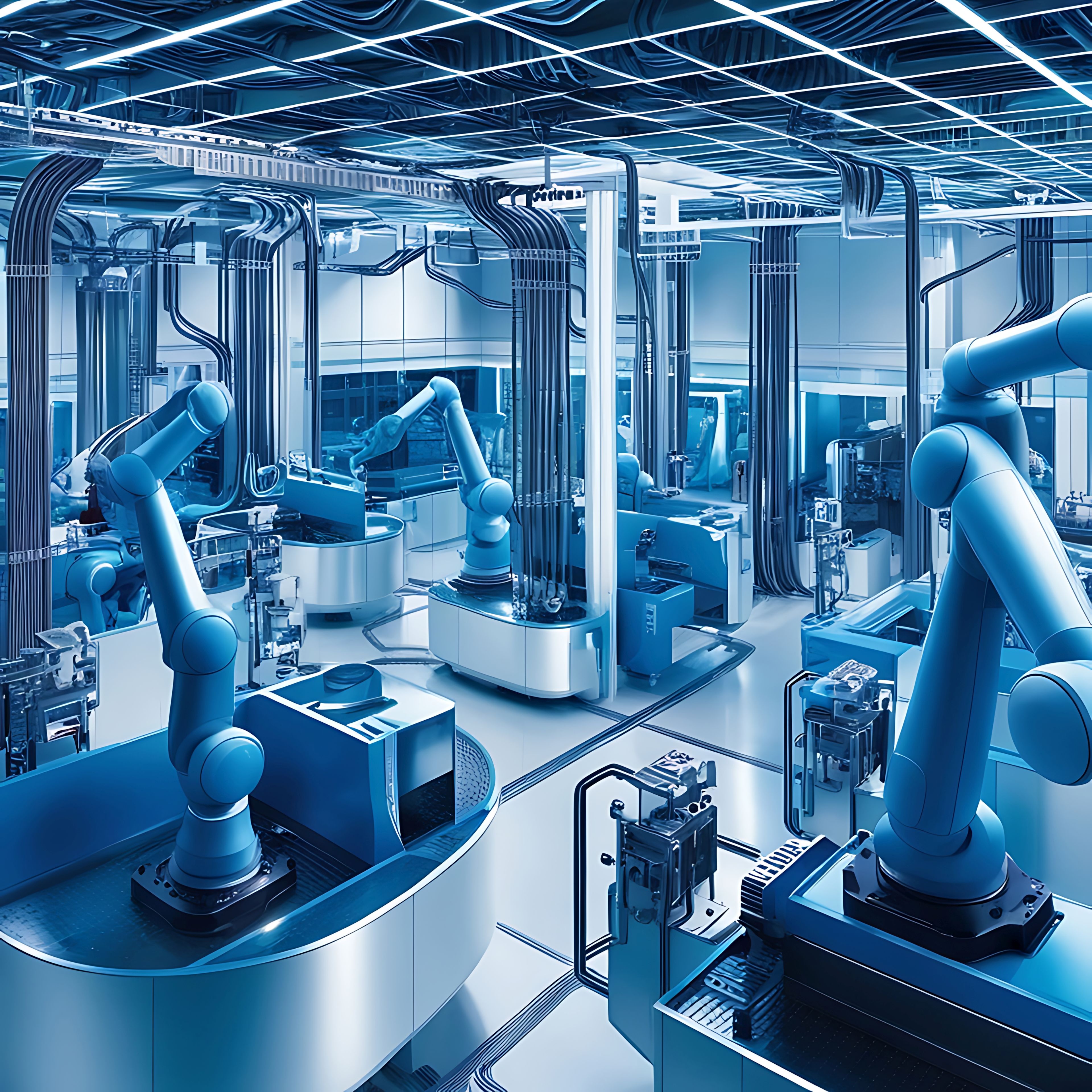

We have implemented automated systems across various industries, including food, pharmaceutical, and construction industries. Our solutions encompass PLC programming, SCADA system development, and integration with existing infrastructure, resulting in increased productivity and reduced operational costs.

MEP Razvoj has successfully implemented advanced automated systems across multiple sectors, including the food, pharmaceutical, and construction industries. Our automation solutions are tailored to optimize production workflows, enhance operational efficiency, and reduce downtime, ultimately driving productivity and cost savings.

Our automation services include:

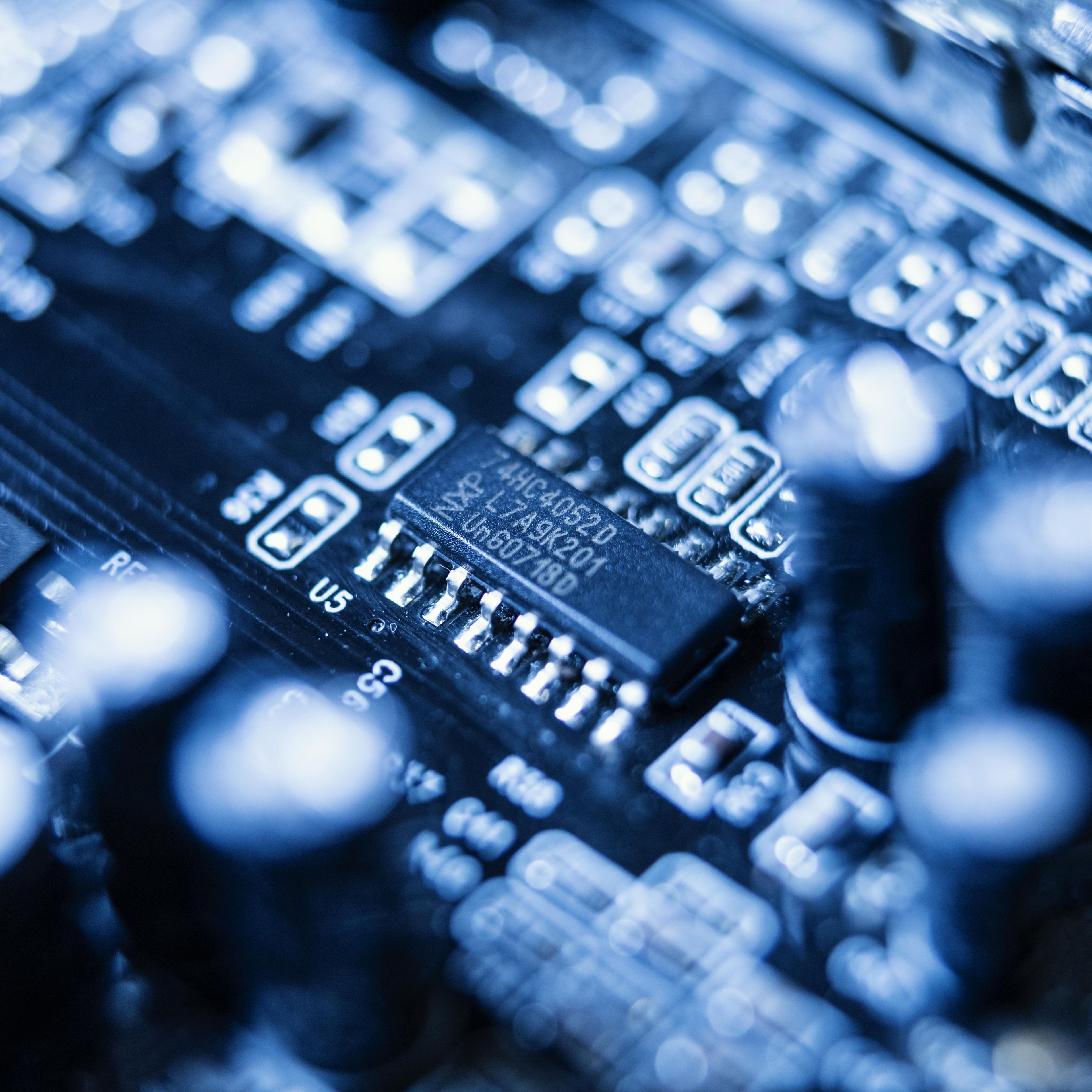

PLC (Programmable Logic Controller) Programming: We design and program PLCs that serve as the backbone of automated machinery and production lines. These controllers enable real-time monitoring and control of industrial processes, ensuring precision and reliability. With our expertise, we create programs that maximize machine efficiency while allowing for easy adjustments based on production needs.

SCADA (Supervisory Control and Data Acquisition) System Development: We design and implement SCADA systems that offer real-time monitoring and control over entire production processes. SCADA systems provide a user-friendly interface that allows operators to track key metrics, control equipment remotely, and respond to potential issues before they escalate, ensuring smoother and safer production operations.

Seamless Integration with Existing Infrastructure: Our automation solutions are designed to integrate smoothly with existing industrial infrastructure, minimizing the need for extensive overhauls. We focus on ensuring that all automation components—from PLCs to SCADA systems—work cohesively with your current equipment, enhancing productivity without disrupting ongoing operations.

By applying our tailored automation solutions, companies in the food, pharmaceutical, and construction industries have benefited from:

Increased Productivity: Automated processes allow for faster production cycles and reduced manual intervention, resulting in a higher output with consistent quality.

Cost Reduction: Through automation, companies can optimize resource usage, reduce waste, and decrease labor costs by minimizing manual tasks.

Improved Operational Safety: With automation systems in place, critical production processes are monitored continuously, ensuring timely detection of potential hazards, reducing the risk of accidents, and ensuring a safer work environment.

Our expertise allows businesses to streamline operations, adapt to market demands more efficiently, and maintain a competitive edge through advanced automation technologies.

Discover more

about Our services:

Related Projects

Project Interactive Museum Exhibitions We have developed interactive exhibits that combine mechatronics and digital technologies to provide visitors with both educational and entertaining experiences. Our solutions include sensor systems, interactive screens, and programmable controllers that enable dynamic interaction with the exhibits. MEP Razvoj specializes in creating dynamic, educational, and engaging interactive exhibits that seamlessly integrate … Continue reading Interactive Museum Exhibitions

Project Production Process Planning Applications We have created advanced software tools for planning and optimizing production processes, enabling companies to manage resources more efficiently, reduce production time, and improve the quality of final products. At MEP Razvoj, we have developed advanced software applications specifically designed for planning and optimizing production processes in industrial settings. These … Continue reading Production Process Planning Applications